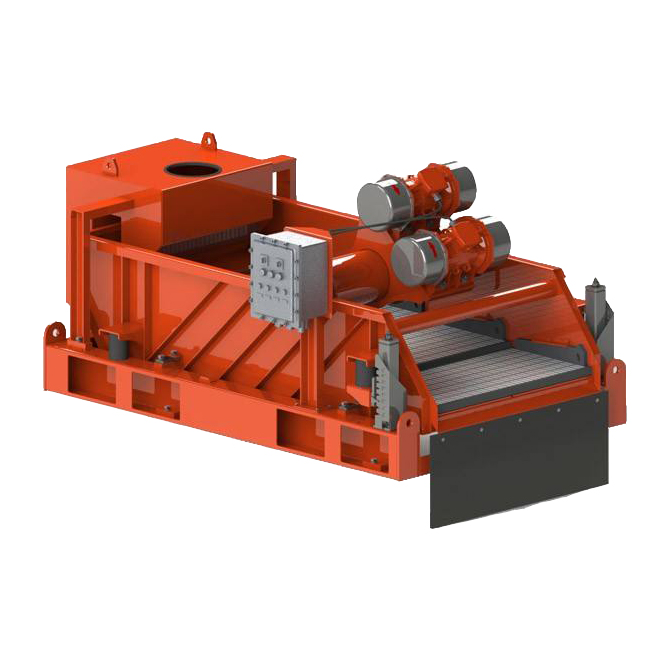

High G dry shaker is designed for drilling cutting’s drying. It can dry the drilling cutting to well delivery condition and does not add any chemicals. The drilling cuttings from solid control shale shaker, then transfered to dry shaker by auger conveyor. The dried cutting was transported away and the water was transfered to decanter centrifuge to second treatment.

Parameters is as floolwing,

| Model | JXHGS804 |

| Vibration mode | Linear motion |

| Treating capacity | 150 m3/h |

| Motor power | 2 x 1.94 KW |

| Screen quantity | 4 pieces |

| Screen size | 1165 x585 mm |

| Screen area | 2.73 m2 |

| Output force | 8.0 G |

| Double amplitude | 4.4-6.34 mm |

| Deck adjustment | -3 -+3° |

| Weir height | 885 mm |

| Explosion-proof | ExDIIBt4 |

| Weight | 1520 kgs |

Dimension | 2650x1650x1425mm |

Features of High G Dry Shaker

1). The G force can reach 8.0G and it also can be adjusted.

2). The deck adjustment is coaxial machinery, so can make sure operation steadily.

3). The shale shaker deck is sealed, the thickness can make sure more than ten years work.

4). The bottom deck is stainless steel material, thus improve the working life.

5). The deck is whole heat treatment, thus can meet the requirement the ling time high vibration work.

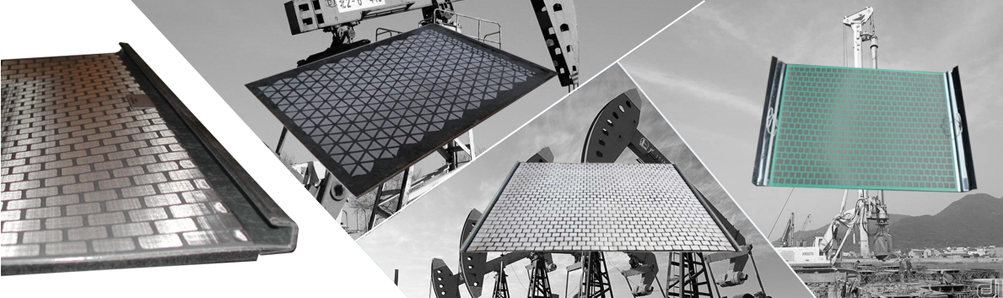

6). The shaker screen is frame plate type, and the wedge-shaped block is easy to change screens.

7). The vibration motor is famous brand, Martin or Oli.

8). The electric control is famous brand, such as Siemens, Schneider and ABB etc.

9). Less vulnerable parts, easy operation and maintenance, all vulnerable accessories can be changed with international brand.

10). Hopper type feeding way design, effectively reduced the height size, convenient for the feed conveyor