Hydrocyclone Desilter is the third phase solid control equipment, the common using cones are 4 inch and 5 inch. The separation size is 15-47μm. According to users’ treating capacity requirement, we can choose a certain number of cones. Desilter is widely used in oil drilling fluid solid control equipment, HDD mud recycling etc. Hydrocyclone desilter has two types, one is contain bottom lillte shakers, the other is without bottom shaker type. If the drilling fluid is heavier drilling fluif, thus can not use the hydrocyclone desilter, for the desilter can remove parts of barites.

Models and Parameters

Model | CNQ100 | CNQ125 | CNQ100W |

Treating capacity | ≤240m3/h (1056GPM) | ≤300m3/h(1320GPM) | ≤240m3/h (1056GPM)

|

Desilter cones | 4" | 5" | 4” |

Cones quantity | 4~12EA | 4~12EA | 4-12EA |

Working pressure | 0.15~0.35Mpa | ||

Feed inlet | 100-150mm | ||

Discharge output | 125-200mm | ||

Separation size | 12~47μm | ||

Bottom shaker screen | 1.0m2 (600×1600mm) Optional | Without Bottom Shaker | |

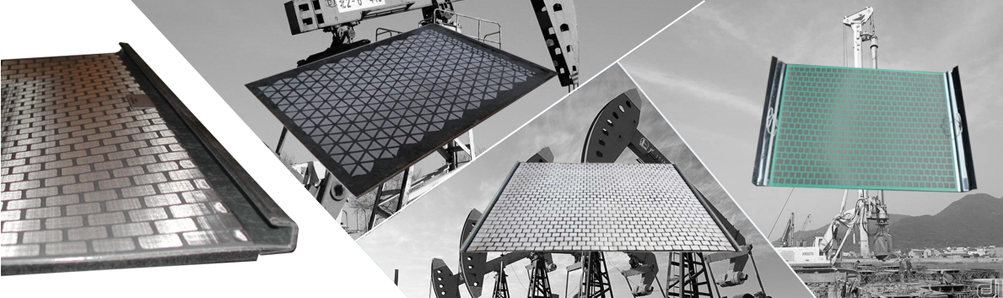

Desilter’s features

1). The desilter can be designed as requirement.

2). Easily operation, the desilter’s spare parts can be changed with international brand.

3). The hydrocyclones are polyurethane material, the light weight is easy maintenance. Cones’s underflow mouth show with pressurized umbrella type dischage sand. So the solids sizes are easily discharged. Thus reduce the block of underflow parts.

4). The vibration motor is Oli, Italvibras Martin

5). The electric elements are SIMENS, Kreuznach and ABB

6). The hydrocyclones’ material is polyurethane.

7). The inlet and discharge connection parts are flange or clamps connection.